At the end of September, I finished my scientific diving training in Finland and headed back home to Ireland. I travelled to a small town in the far south of the country called Castletownbere in County Cork. It is a fishing port village, backed by beautiful mountains, facing onto the Atlantic Ocean, sheltered by the headland of the Beara Peninsula and Bere Island.

I had come here to take part in commercial diver training, this training is the first step that many divers take into the professional diving industry. It is a legal requirement in Ireland, the UK and many other countries around the world to have commercial diver training in order to be employed by someone to carry out any diving work such as engineering, construction or maintenance and in many cases this also includes scientific, media or even military diving. Essentially for anyone that is planning a career in the underwater world in a further capacity than the recreational or technical diving industry, commercial diving training is pretty much essential.

I was joined in Castletownbere at the BIM National Fisheries and Diving College by a group of equally enthusiastic candidates from various industries and diving backgrounds; engineers, fish farmers, construction workers or like myself planning a career in scientific diving. It was eye opening for me to meet people with such different motivations to train as commercial divers and draws to the sea.

We began on Monday morning bright and early in the classroom for diving briefings and dive theory. In our first few days we practised basic dive skills, getting everyone onto the same level and then cracked on with swim tests, full face mask training and rescue drills. The rescue drills began with assessing an unconscious buddy on the surface and carried through towing with rescue breaths, shore egress, shoreside scene management with CPR and O2 administration. Needless to say, we had our work cut out as we repeated the rescue scenario until each diver had polished the set of skills to demonstration level. It was rigorous but the progression of each diver during the course was incredible.

After a week of shore diving and training in various navigation and search and recovery training, we headed out to the ‘Sandfisher’ a purpose built barge, moored off Bere Island as the perfect training platform for the course. Out on the barge we had a high pressure compressor for filling tanks after each dive, a surface supplied diving station and low pressure compressor, a hyperbaric recompression chamber, galley, head and mess. It was an ideal set up for the course and meant that as a team of students and instructors, we could run a full day of diving incredibly efficiently.

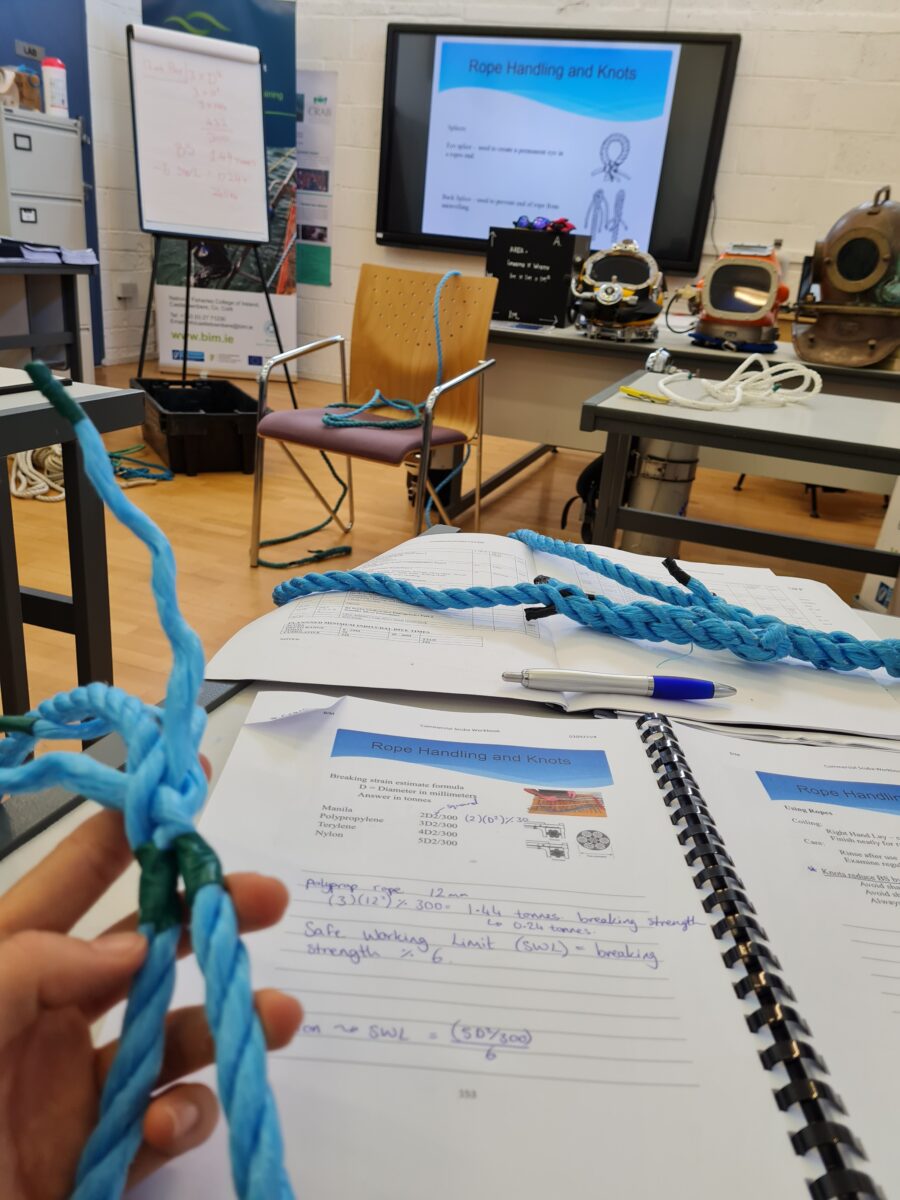

We began most mornings with classroom sessions covering everything from diving physics equations to rope splicing and equipment servicing. I found it fascinating to learn more about the world of commercial diving and also it was great to learn from instructors with such incredible depth of knowledge on each specialist topic. Our course director Brian Murphy led most of our classroom sessions with a wealth of knowledge from over 40 years of experience in the diving industry as a commercial diver and instructor having worked in the North Sea and around the world as a mixed gas saturation diver and dive supervisor. He covered every aspect of diving physiology, physics and legislation with us. Our instructor for all things equipment was Cillian Gray, who is one of the leading dive equipment technicians in the country, also with a wealth of experience as a commercial diver in the inshore aquaculture, civil engineering and scientific industries.

We were also joined by Tiernan Gray who is a life support and diving supervisor and instructor having worked at sea for many years both offshore and inshore. He taught us about first aid and diver rescue as well as how to run a dive team smoothly and without opportunity for accidents or injuries. We were incredibly lucky that each topic covered on the course was taught to us by an expert in that field, meaning that any and all questions we had were answered in detail and often with real life analogy to bring the learning home.

After theory and dry skills, we would head out to the barge for our day’s diving. Normally it would be two dives a day and when you weren’t diving, you were the surface support of ‘tender’ to a diver’s comms line, deck watch or fully dressed in and ready as a ‘standby diver’ able to hit the water at a moment’s notice. We practised standby diver drills many times during the course, our diving supervisor made sure that the standby diver could hit the water with less than a minute of notice. It was fantastic to have the opportunity to train in what became a highly efficient and effective team during the course.

Towards the end of the course we were given various tasks as a group to complete for which we wrote up risk assessments and detailed project plans. Our projects varied from tasks such as close visual inspections of a subject to assess any damage or missing elements, for example a mooring line, anchor and chain or in one case a waste water outlet diffuser or ‘pig’. During these assessments we used cameras, callipers and other measurement tools to get exact diameters of chains or bolts to look for any corrosive or gross structural damage. After each task, much like any other working commercial dive team, we wrote up survey reports.

We also were given more physical tasks such as cutting specific lengths of rebar that were communicated to us from the surface using an underwater workbench and hacksaw. These tasks were demanding but also I felt invigorated and enjoyed the challenge, it was a type of diving I had never before experienced. I am thrilled to have opened up a whole range of new skills. Installing fixed scientific experiments underwater will not seem such a daunting task to me anymore.

We were taught a lot about the world of commercial diving and used the US Navy tables to plan theoretical dives and tasks to the second, taking into account the effects of pressure and workload on our diver’s potential gas consumption. These decompression theory learnings were fixed concretely in our minds after our hyperbaric chamber training where we learnt how to carry out the internal and external pre-checks and how a recompression treatment is run from start to finish.

Also we got to experience our first ever chamber dives to 40m and the joys thereof. We were given to take into the chamber with us a balloon, polystyrene cup, neoprene hood, puzzles and a maths and phonetic alphabet test. It was incredible to see how compressed and small the balloon, polystyrene and neoprene hood became and equally incredible to read all of the answers we had written in the test while ‘under the influence’ at 40m depth. Watching each group go for their chamber dive was quite a hilarious thing, each student was asked to count slowly to ten once at 40m, who knew such hilarity could arise from simply saying the number 3.

By the end of the five week commercial diver course, we had covered everything from diving physics and physiology, the ins and outs of a commercial scuba set up and its repair to communication systems, working underwater, chartwork and hyperbaric chamber operations. It was an intensive and challenging few weeks but at the end we each had been given a wealth of knowledge and had grown as divers and as a team. I am so glad to have been trained by the calibre of diving instructors at BIM but also with the friendship and joy of working with a great team.

Thank you very much to all of the incredible hosts and sponsors of my scholarship this year for making it possible for me to take part in this training programme. I am absolutely thrilled and blessed to be given such an opportunity!

Thank you to Rolex and OWUSS for making dreams come true. Also thank you to my incredible equipment sponsors

Fourth Element, Suunto, Halcyon Divesystems, Reef Photo and Video, Nauticam and Reel Diving.